3D rebar modeling is a revolutionary construction technique utilizing advanced software to create precise digital models of steel reinforcing bars (rebar) within concrete structures. This method offers significant advantages over traditional 2D methods, including enhanced accuracy, efficiency, and structural integrity. By providing a comprehensive 3D view, it enables optimized reinforcement design, reduced material waste, improved project management, and early detection of potential conflicts, ultimately leading to cost savings and increased project efficiency. Best practices involve using industry-standard software with features like precise dimensioning, dynamic manipulation, clash detection, standardized naming conventions, clear project parameter definitions, and regular reviews for accuracy.

In the realm of construction, precise reinforcement placement is paramount for structural integrity. This is where 3D rebar modeling emerges as a game-changer. By transitioning from 2D plans to immersive 3D models, engineers and contractors gain a dynamic perspective, enabling better visualization and analysis. This article explores the transformative power of 3D rebar modeling, delving into its benefits, key software features, and best practices for accurate and efficient reinforcement placement in today’s digital era.

Understanding 3D Rebar Modeling: The Basics

Understanding 3D Rebar Modeling: The Basics

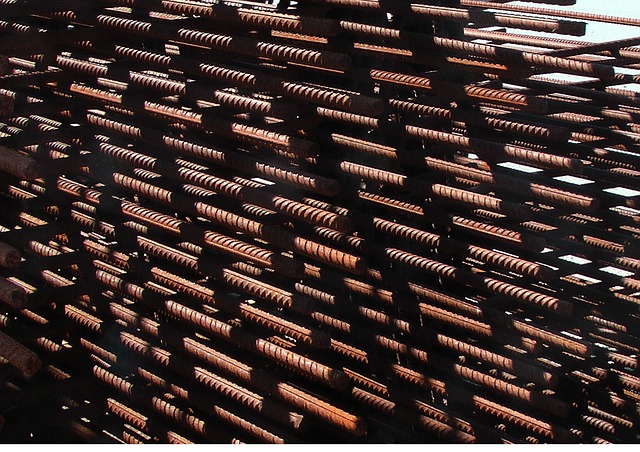

3D rebar modeling is a cutting-edge technique that allows engineers and construction professionals to precisely visualize and plan reinforcement placement in concrete structures. By creating detailed digital models of rebar (steel reinforcing bars), this technology offers an innovative solution for ensuring structural integrity and efficiency. In traditional construction methods, rebar layout is often done manually, leading to potential errors and time-consuming processes. However, 3D rebar modeling streamlines the entire process by providing a comprehensive, three-dimensional view of the structure, enabling more accurate and optimized reinforcement design.

This advanced modeling approach involves utilizing specialized software to generate and manipulate digital representations of rebar elements within a structured environment. Engineers can then simulate various scenarios, ensuring that each rebar is placed optimally to meet structural requirements while minimizing material waste. With its ability to enhance accuracy, reduce costs, and improve overall project management, 3D rebar modeling has become an indispensable tool in the modern construction industry, revolutionizing how we approach reinforcement planning.

Benefits of 3D Modeling for Reinforcement Placement

In today’s construction industry, precision is key, especially when it comes to reinforcement placement in concrete structures. This is where 3D rebar modeling emerges as a game-changer. By utilizing advanced 3D modeling software, engineers and contractors can create detailed digital representations of the building or infrastructure project. This innovative approach offers numerous advantages over traditional 2D methods. Firstly, it allows for a comprehensive visual understanding of the entire structure, enabling better spatial awareness during the construction process.

The benefits are far-reaching; accurate 3D models facilitate efficient planning and coordination among various stakeholders. They provide a clear picture of the reinforcement layout, ensuring that rebar is precisely placed according to design specifications. This reduces errors, saves time, and optimizes material usage. Moreover, 3D modeling enables early detection of potential conflicts or issues, allowing for prompt solutions before physical construction begins, ultimately leading to cost savings and project efficiency.

Key Features and Tools in Advanced 3D Rebar Modeling Software

Advanced 3D rebar modeling software offers a suite of key features designed to enhance precision and efficiency in reinforcement placement for construction projects. These tools allow engineers and contractors to visualize, manipulate, and optimize rebar configurations in a three-dimensional space, ensuring structural integrity and cost-effectiveness. Features include intuitive CAD capabilities, real-time visualization, and automated calculation of material properties based on rebar geometry.

The software leverages cutting-edge technology to streamline the rebar modeling process. It provides comprehensive drawing tools for creating detailed rebar layouts, enabling users to precisely define bar dimensions, bends, and connections. Additionally, advanced simulation capabilities allow for virtual testing of different reinforcement scenarios, helping to identify potential issues before construction begins. This level of digital precision not only speeds up project timelines but also contributes to safer and more sustainable building practices.

Best Practices for Accurate and Efficient 3D Rebar Modeling

Engaging in best practices for 3D rebar modeling ensures precise and efficient reinforcement placement, ultimately enhancing structural integrity. Firstly, utilizing industry-standard software designed specifically for steel detailing is paramount. These tools offer advanced features like accurate dimensioning, dynamic manipulation, and clash detection, streamlining the design process. Incorporating a standardized naming convention for rebar elements not only improves organization but also facilitates collaboration among team members.

Moreover, defining clear project parameters—including material types, bar sizes, and structural requirements—before beginning modeling is crucial. This foundational step allows for consistent and realistic 3D representations, avoiding potential errors later in the process. Regular reviews and quality checks at intermediate stages of modeling help identify and rectify inaccuracies early, ensuring the final product aligns with design intent.

3D rebar modeling is transforming the way structural engineers approach reinforcement placement, offering unparalleled accuracy and efficiency compared to traditional 2D methods. By leveraging advanced software tools and adopting best practices, professionals can streamline their design processes, reduce errors, and optimize concrete structures. The benefits of 3D rebar modeling are clear: improved precision, enhanced visualization, and better overall project outcomes. As the construction industry continues to embrace digital transformation, 3D rebar modeling will undoubtedly become an indispensable tool for achieving successful and safe infrastructure development.