Building Information Modeling (BIM) is a game-changer in structural engineering and architecture, offering precise 3D visualization of steel reinforcement networks. By mapping bar placement, size, and connections, BIM software enhances design clarity, enables advanced analyses like clash detection, and minimizes errors throughout construction. This technology has revolutionized rebar detailing, ensuring high-quality, safe structures through early issue identification and streamlined data management. Effective implementation requires training, standardized models, parametric modeling, regular updates, coordination meetings, and quality assurance checks, ultimately improving project efficiency and understanding for BIM users.

In today’s construction landscape, clear visualization is key to success. This is especially true for complex structures like reinforcement and steel frameworks, where intricate details can be easily overlooked. This article explores the transformative power of 3D visualization in the context of BIM (Building Information Modeling) for rebar detailing. By delving into the benefits and implementation practices, we uncover how this technology enhances planning, improves accuracy, and fosters collaboration, ultimately streamlining construction projects.

Understanding BIM (Building Information Modeling) for Reinforcement

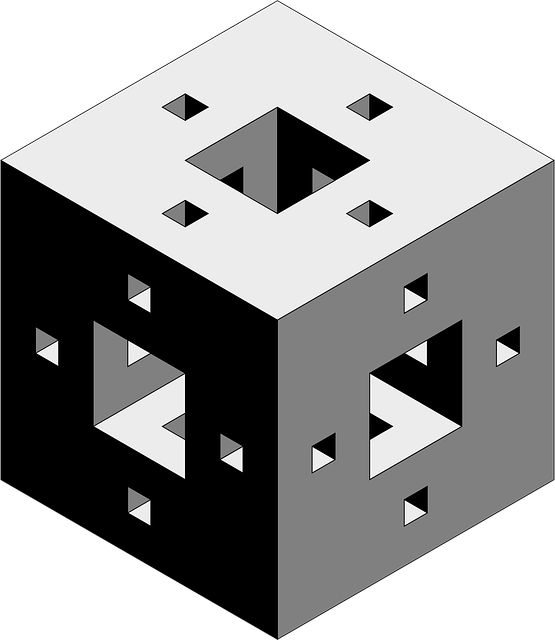

Building Information Modeling (BIM) is transforming the way structural engineers and architects design, document, and manage reinforcement and steel structures. At its core, BIM involves creating a digital representation of a building that incorporates all relevant information about every element within it. For rebar detailing, this means meticulously mapping out the placement, size, and connection points of each piece of reinforcing bar (rebar) in 3D space.

By leveraging BIM software, professionals can achieve unprecedented clarity and accuracy in their designs. They can visualize the entire structural system interdependently, ensuring that rebar layouts seamlessly integrate with other building components like concrete slabs, columns, and beams. This holistic view not only streamlines design processes but also enhances collaboration among project stakeholders. Moreover, BIM enables advanced analysis capabilities, such as clash detection and material takeoffs, which help avoid costly errors during construction.

Rebar Detailing: The Essential Role of Visualization

In the realm of construction, reinforcement and steel structures play a pivotal role in ensuring the integrity and durability of buildings. Among various techniques used to plan and execute these intricate designs, BIM (Building Information Modeling) has emerged as a game-changer, particularly in rebar detailing. Rebar, or steel reinforcing bar, is an indispensable component in concrete structures, providing strength and reinforcement against various loads. However, the complex nature of rebar networks makes precise visualization critical for avoiding errors and inefficiencies.

BIM for rebar detailing offers a sophisticated solution by enabling engineers and architects to create detailed 3D models that accurately represent the placement and interconnection of rebars within a structure. This level of visualization goes beyond traditional 2D drawings, providing a comprehensive understanding of the entire system. By leveraging BIM, project stakeholders can identify potential conflicts or issues early in the design phase, streamline construction processes, and ultimately deliver high-quality, safe, and efficient structures.

Benefits of 3D Visualization in Steel Structure Planning

The introduction of 3D visualization techniques has revolutionized steel structure planning, offering numerous benefits over traditional 2D methods. One of the most significant advantages is the ability to create a comprehensive and accurate digital representation of complex reinforcement and steel frameworks. This visual approach allows engineers and architects to gain a deeper understanding of the design, identifying potential issues and conflicts early in the planning phase.

By utilizing BIM (Building Information Modeling) for rebar detailing, professionals can efficiently manage and organize the vast amount of data associated with steel structures. 3D visualization tools provide an immersive experience, enabling stakeholders to walk through the digital model, check connectivity, and ensure proper placement of rebar reinforcement. This enhances collaboration, reduces errors, and streamlines the design process, ultimately leading to more efficient construction and better overall results.

Implementation and Best Practices for Effective BIM in Construction

The successful implementation of Building Information Modeling (BIM) in construction, particularly for reinforcement and steel structures, involves a structured approach. Start by ensuring all project stakeholders are trained in BIM software and workflows relevant to rebar detailing. Standardized models, including accurate geometry and material properties, should be developed early in the design phase. This enables efficient collaboration and clash detection between different disciplines.

Best practices include maintaining a clear and consistent data structure, utilizing parametric modeling for rebar elements, and regularly reviewing and updating models. Coordination meetings and regular checks with quality assurance teams are vital to ensure the integrity of BIM models throughout construction. Incorporating BIM for rebar detailing enhances accuracy, reduces errors, and streamlines processes, ultimately contributing to project efficiency and better overall understanding.

The integration of BIM (Building Information Modeling) into reinforcement and steel structure planning has revolutionized the construction industry. By leveraging 3D visualization, engineers and contractors gain a clearer understanding of complex designs, enabling more efficient rebarlist creation and detail development. This approach not only enhances accuracy but also streamlines project workflows, leading to cost savings and timely project completion. Adopting best practices for effective BIM implementation ensures that the benefits of this technology are maximized across the construction lifecycle.